Yield strength of steel bar 187478-Yield strength of 316 stainless steel bar

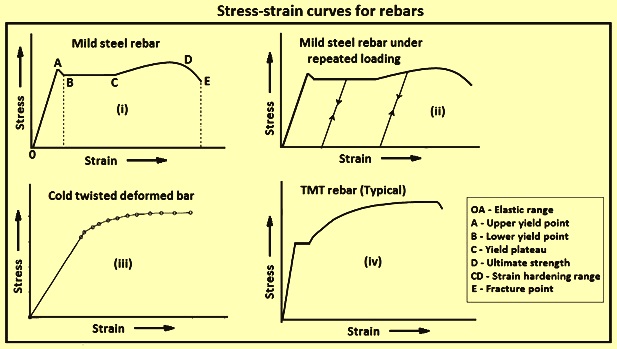

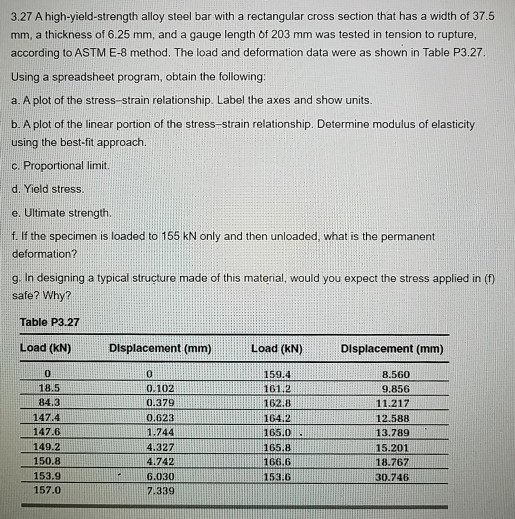

* Threadbar size not listed in the ASTM A 722 but its strength is in conformance with this standard WARNING DO NOT WELD on or near 22 prestressing bars or their anchorages DYWIDAG THREADBAR® Properties – Reinforcing Steel per ASTM A615 THREADBAR® Designation Maximum THREADBAR® Diameter Minimum Yield Stress (f y) Nominal Cross SectionCharacteristic strength of steel reinforcement is the material parameter most needed for reinforced concrete designs According to Eurocode 2 (EN 1992–1–1 04), the characteristic yield strengthMild steel bars also are known as Fe 250 because the yield strength of this steel is 250 N/mm2 The stressstrain curve for mild steel is given in the figure It shows a clear, definite yield point Mild steel bars are ductile, they are not preferred over high yield strength deformed bars because it has less strength and weak bond

The Steel Bar Has A X 10 Mm Rectangular Cross Section And Is Welded Along Section A A The Weld Material Has A Tensile Yield Strength Of 325 Mpa And A Shear

Yield strength of 316 stainless steel bar

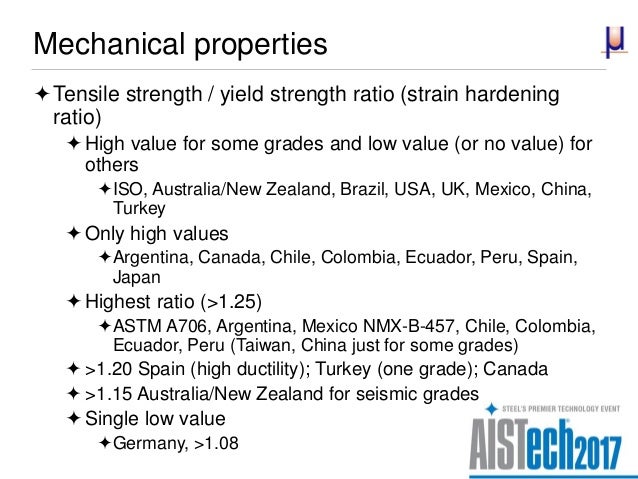

Yield strength of 316 stainless steel bar-This test is done to determine how the material reacts when you apply force on it Usually, by pulling the metal, you identify the material's tensile strength, yield strength as well as how much it will elongate Tension test is one of the critical criteria where you submit a steel bar sample to tension which is under control until failure stageProduct and testing standards for reinforcement bar products In addition to specifying properties, such as the minimum upper yield strength (Reh), Rm/Reh ratio, and elongation values for ribbed steel bar products, ISO product standards, such as ISO , also specify how the tensile properties are to be measured Unique testing

Reinforcing Material Charectristic Strength And Types Of Steel Reinforcement

The Old Metallurgical Engineer and Steelmaker says If you mean steel reinforcing bars for concrete, then 50,000psi and 60,000psi yield strength are quite common But if you mean other steel bars, the yield strength can vary from 41,300psi to 116,000psiGrades 550, 650, and 700 MPa were purposely selected with the intention to examine if these higher grades are still promising to be implemented in special structural systems since they are prohibited by the building codes for longitudinal reinforcement, whereas Grade 4 MPa bars are the maximum limit of yield strength of reinforcing bars that is allowable for longitudinal reinforcement of special structural systemsRexton Steel & Alloys is the leading suppliers and stockists of S235JR Carbon Steel Round Bars, Mild Steel S235JR Bar, MS S235JR Rods, High Yield Strength S235JR Bars, Low Carbon Steel Rods in Mumbai, India

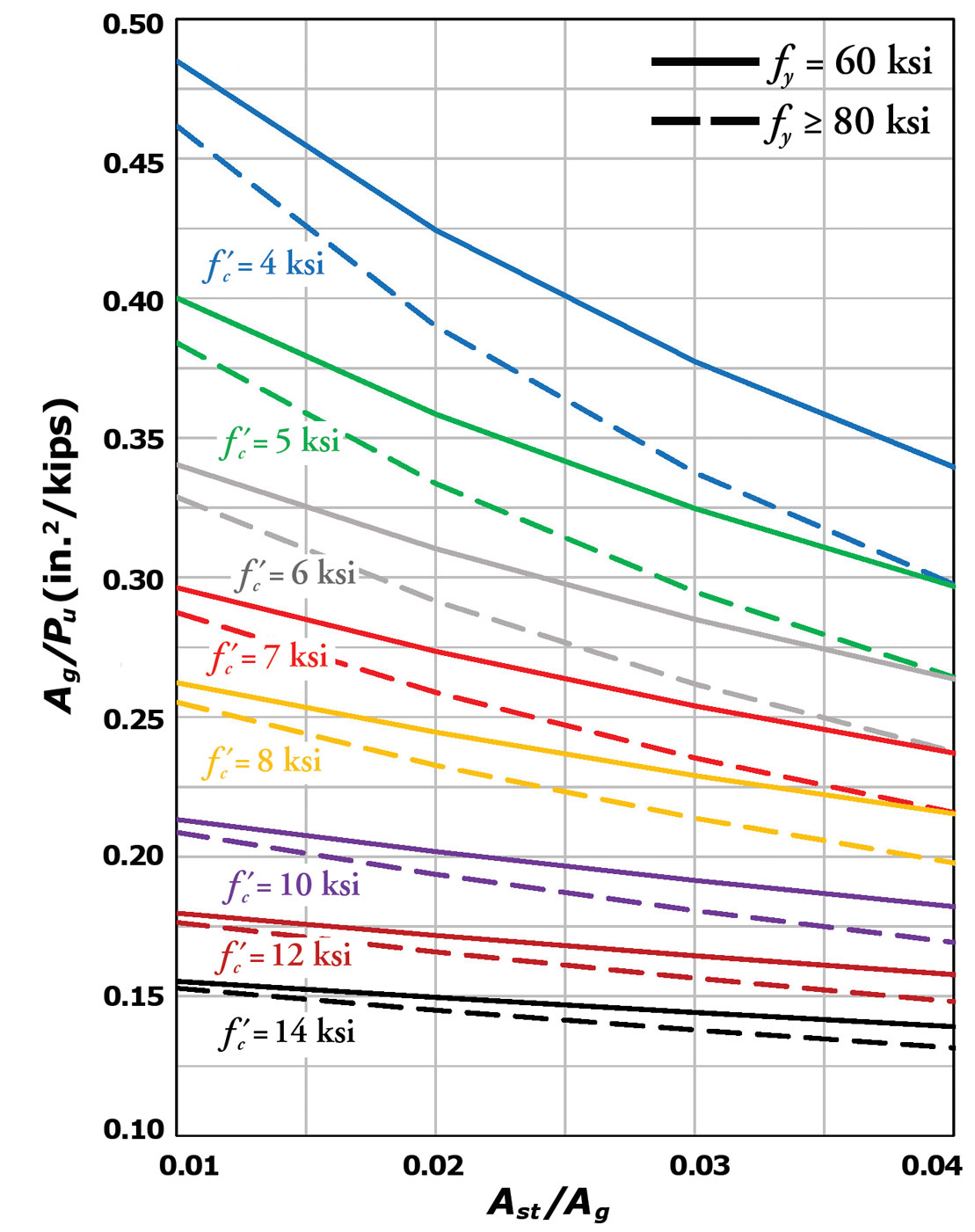

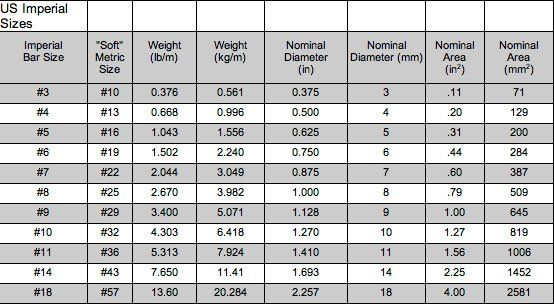

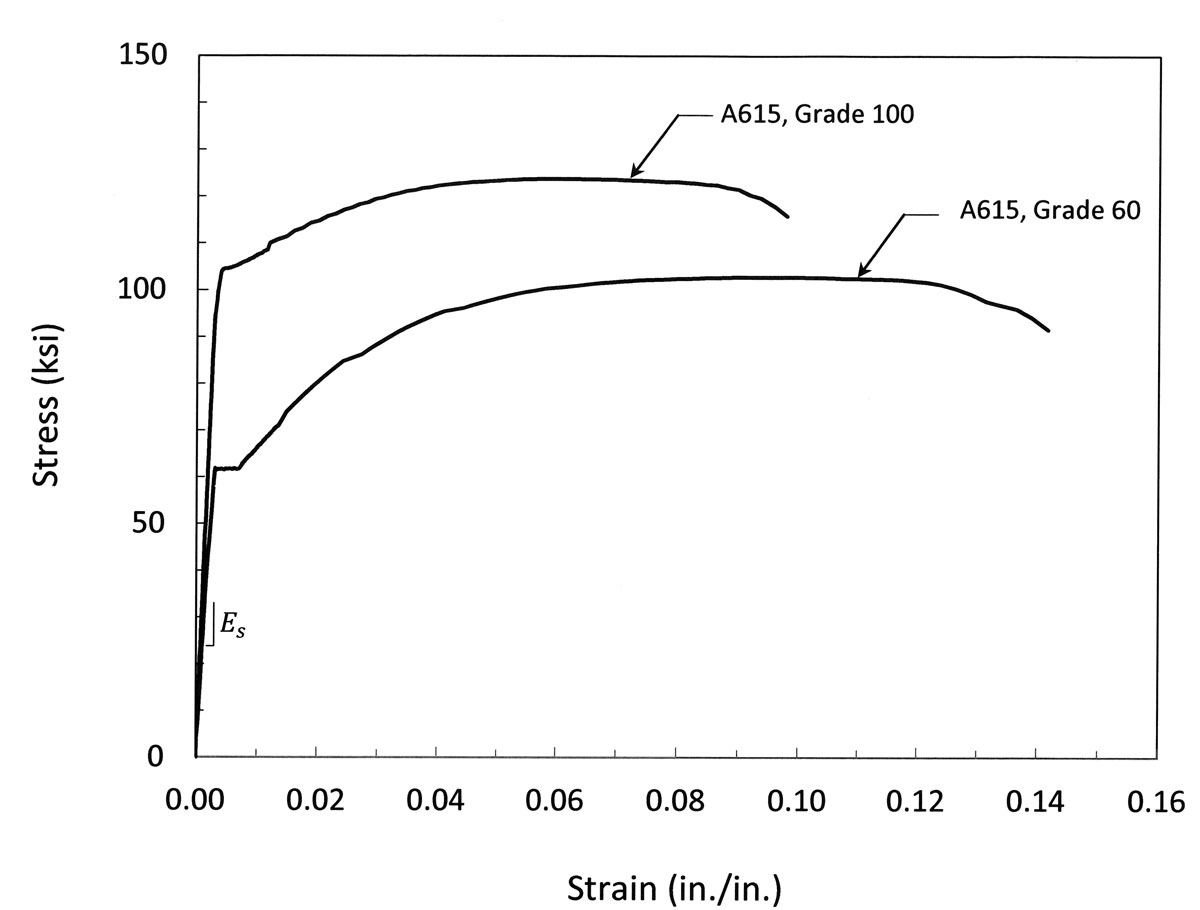

Grade 60 reinforcing steel, with a yield strength of 60,000 psi, is the most commonly used grade in North America Recent advances have enabled reinforcing steels of higher strengths to be commercially produced Highstrength reinforcing bars (HSRB) are typically considered to be any reinforcing bar with a yield strength greater than 60,000 psiStrength is a critical factor in metal uses, for example, some applications require stronger aluminum parts, while some products need high steel hardness or yield strength of steel, this may determine the selection of CNC machining material or product design Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart ofThe lockoff load should not exceed 70%of the specified minimum tensile strength of the prestressing steel The maximum test load should not exceed 80% of the specified minimum tensile strength of the prestressing steel Maximum test load and maximum factored design load must not exceed the yield strength of ANY steel element Structural Properties

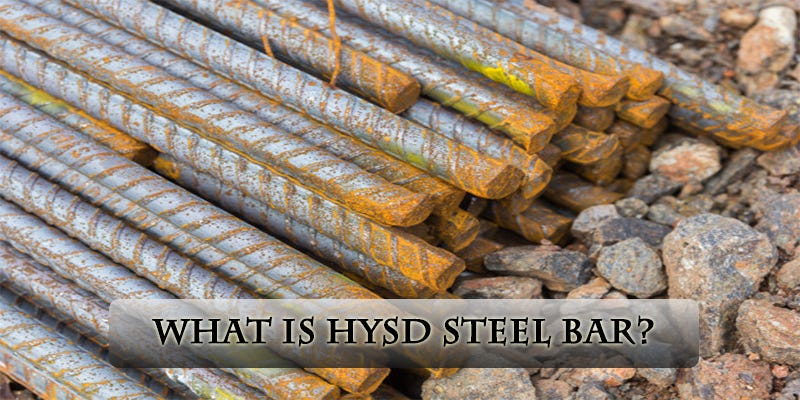

HYSD bars are preferred as reinforcement in RCC over plain mild steel bars, due to following reasons Higher Strength HYSD bars have yield strength, higher than that of plain mild steel bars Better Bond The HYSD bars have better bond with concrete due to corrugations or ribs on the surface of the bars As per IS 456 00, the bond2 Cold worked high yield strength bars The (2) type of steel is also called as CTD (Cold Twisted Deformed) bars or Tor steel and are available in two grades Deformed bars are represented by symbol # 1 Fe 415 or Tor 40 2 Fe 500 or Tor 50 A twisted deformed bar has about 50% higher yield stress than plain bars A deformed bar has corrugation or ribs on the surface of the bar, to increase the bond and prevent slipping of the bar in concreteThe lockoff load should not exceed 70%of the specified minimum tensile strength of the prestressing steel The maximum test load should not exceed 80% of the specified minimum tensile strength of the prestressing steel Maximum test load and maximum factored design load must not exceed the yield strength of ANY steel element Structural Properties

Flexural Behavior Of Beams Reinforced With Steel Bars Exceeding The Nominal Yield Strength

Reinforcing Material Charectristic Strength And Types Of Steel Reinforcement

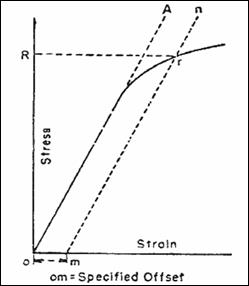

The 02% proof strength In some steels, for example cold worked steels, no yield effect is observed, the stress strain plot showing a continuous curve after the linear elastic portion (Figure 2)Mild steel bars also are known as Fe 250 because the yield strength of this steel is 250 N/mm2 The stressstrain curve for mild steel is given in the figure It shows a clear, definite yield point Mild steel bars are ductile, they are not preferred over high yield strength deformed bars because it has less strength and weak bondHigh yield steel bars for the reinforcement characteristic strength the value of yield strength, having a prescribed probability of not being attained in a hypothetical unlimited test series The characteristic value is the lower limit of the one sided statistical tolerance interval at which

Crsi Rebar Properties

Tensile Strength Yield Strength Ts Ys Ratios Of High Strength Steel Hss Reinforcing Bars Aip Conference Proceedings Vol 1964 No 1

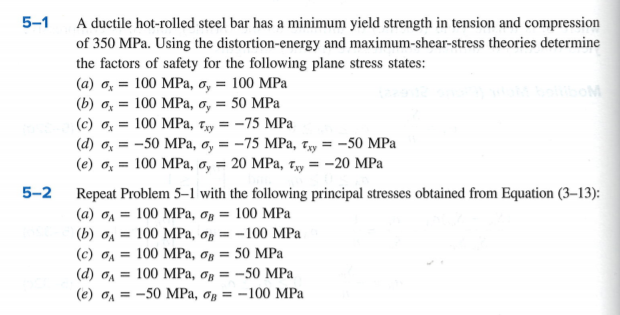

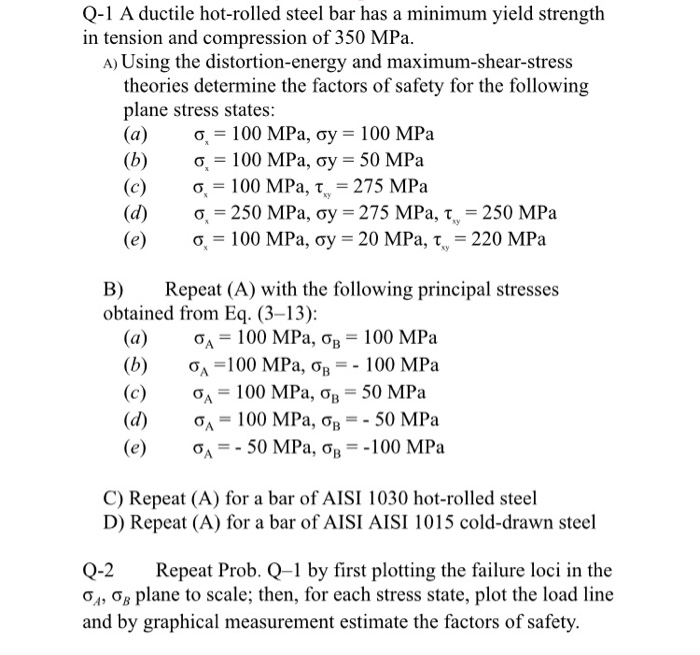

Tensile Strength 64,000 psi Yield Strength 54,000 psi Elongation in 2" 15% Reduction of Area 40% Brinell Hardness 126A ductile hot rolled steel bar has a minimum yield strength in tension and compression of 350 MPa Using the distortion energy and maximum shear stress theories Determine the factor of safety for following plane stress statesHigh yield steel bars for the reinforcement characteristic strength the value of yield strength, having a prescribed probability of not being attained in a hypothetical unlimited test series The characteristic value is the lower limit of the one sided statistical tolerance interval at which

Sae Aisi 1080 Steel Properties Heat Treatment Composition Rockwell Hardness

Q Tbn And9gctkrzf52tulw Hck4iec8kqmmvrheff2kzrugh6dmtmgku6pybl Usqp Cau

Yield strength of steel connecting bars To protect against earthquake damage, steel beams are typically fitted and connected with plastic hinges However, theYield strength σ y Yield strength is defined in engineering as the amount of stress (Yield point) that a material can undergo before moving from elastic deformation into plastic deformation Yielding a material deforms permanently;In the Philippines, the local term for rebars is "kabilya" but it may also be referred to by engineers and site personnel as reinforcing steel bars, deformed bars (debars) or concrete reinforcementsThe PNS 49 is the national rebar standard, it details the technical specifications of rebars per grade, class, and size

Strength Of The Steel Rod Samples Download Scientific Diagram

Reinforcement Steel Ispatguru

A36 steel has a Poisson's ratio of 032, and a shear modulus of 78 GPa (11,300,000 psi) A36 steel in plates, bars, and shapes with a thickness of less than 8 in (3 mm) has a minimum yield strength of 36,000 psi (250 MPa) and ultimate tensile strength of 58,000–80,000 psi (400–550 MPa)Dia of Bar Yield Load(Tons) Ultimate load(Tons) Area of Bar, A=∏ D 2 /4 YieldUltimate Strength (fu) = 410MPa or 400MPa(Sometimes depends on loading conditions and environmental conditions) For HYSDYield Strength (fy) = 415 MPa or 500 MPa (depends on the carbon content and other alloys mixed into it Ultimate strength (fu) = 485 MPa for Fe415 and 5

A Steel Rod Of Diameter D 50mm Yield Strength Of 260 Mpa Supports An Axial Load P 50r And A Vertical Load R Acting At The End Of A 0 8m Long Bar

Steel Reinforcement Types And Their Properties

For Mild SteelYield Strength(fy) = 250MPa;A 72mmwide by 7mmthick steel bar, with a yield strength of 275 MPa and bearing strength of 360 MPa, is attached to a wood support beam with four 25 mmdiameter lag screws having ultimate shear strength of 165 MPa Design requirement asks for factor of safety of 175 and 30 with respect to yield strength and bearing strength of the barYIELD STRENGTH GRADE40 GRADE60 GRADE75 Min 40,000 Psi 60,000 Psi 75,000 Psi Max 60,000 Psi 70,000 Psi 100,000 Psi

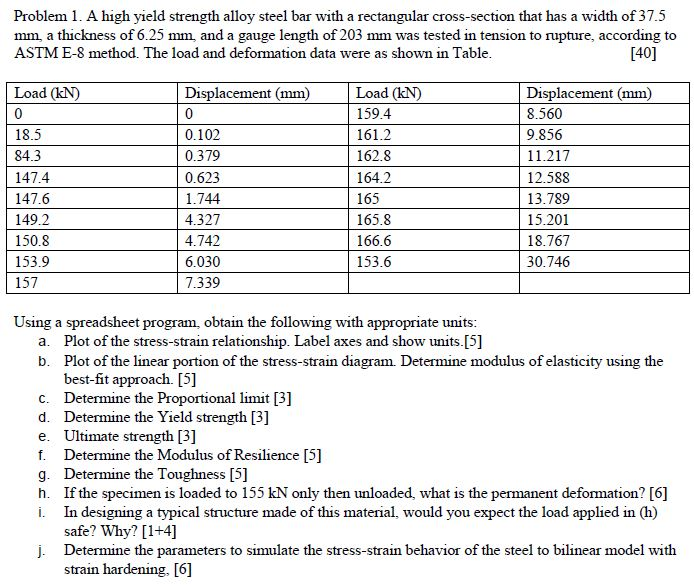

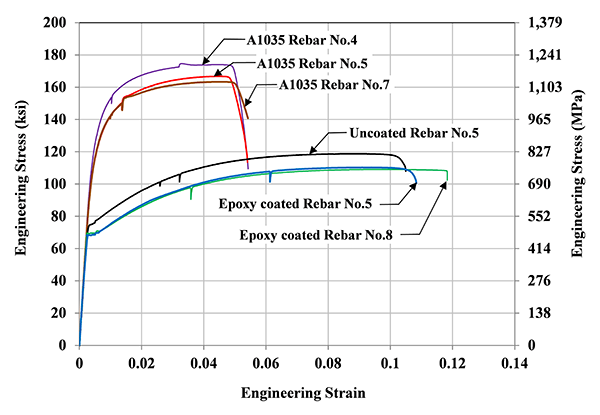

Solved Problem 1 A High Yield Strength Alloy Steel Bar W Chegg Com

The Steel Bar Has A X 10 Mm Rectangular Cross Section And Is Welded Along Section A A The Weld Material Has A Tensile Yield Strength Of 325 Mpa And A Shear

HOT ROLLED NON WELDABLE DEFORMED STEEL BAR 230 230 390 D*25mm D*25mm 18 18 180 3d 4d WHITE 275 275 480 D*25mm D*25mm 10 8 180 4d 5d YELLOWYield Strength Tensile Strength % Elong MPa (ksi) MPa (ksi) Steel Alloy A36 Hot rolledA 72mmwide by 7mmthick steel bar, with a yield strength of 275 MPa and bearing strength of 360 MPa, is attached to a wood support beam with four 25 mmdiameter lag screws having ultimate shear strength of 165 MPa Design requirement asks for factor of safety of 175 and 30 with respect to yield strength and bearing strength of the bar

Yield Strength Of Steel

Www Utoledo Edu Engineering Faculty Serhan Guner Docs B5 Vt5materialproperties Pdf

Alternatively, the yield strength can be defined as the stress at a permanent strain of 02% (Figure 1);I have a flat steel bar (30 mm width, 5 mm thick, 1100 mm long) The bar has a load applied in the centre of 100N the bar is fixed at both ends with a single concentrated load P applied midspan the maximum yield stress is 250 MPa (250x10^6 Pa)Grade 60 rebar offers a minimum yield strength of 60,000 pounds per square inch, or 4 megapascals on the metric grading scale It also features a continuous line system, with one line running along the length of the bar which is offset a minimum of five spaces from the center

Kinds Of Steel Reinforcement Bars Used In Concrete Structure By Hickman Love Tipton Ltd Issuu

Ribbed Steel Bars Reinforcement Reliable Reinforcement

HighStrength Reinforcing Bars Introduction Grade 60 reinforcing steel, with a yield strength of 60,000 psi, is the most commonly used Grade in North America Recent advances have enabled reinforcing steels of higher strengths to be commercially produced In ATC 115 (ATC 14), highstrength reinforcing bars (HSRB) were considered anyASTM A572 Grade 50 Steel ASTM A572 grade 50 steel is a lowalloy highstrength structural steel with a yield strength of 50 ksi (345 MPa) and a tensile strength of 65 ksi (450 MPa) It has better mechanical properties than ASTM A36 steel ASTM A572 contains 5 yield point grades Grade 42, Grade 50, Grade 55, Grade 60 and Grade 65Note Maximum allowable temporary tension is 90% of minimum yield load Mill length is 60 ft (#6 through #24) and 53 ft for #28 * Threadbar sizes not listed by ASTM A 615 but yield strength is in conformance with A615 standard

Rebar Tensile Strength Test Koury Engineering Youtube

Http Files Engineering Com Download Aspx Folder 4d 3553 4be1 B8e8 4f10ba248a68 File Crsi Edr No 48 Pdf

This test is done to determine how the material reacts when you apply force on it Usually, by pulling the metal, you identify the material's tensile strength, yield strength as well as how much it will elongate Tension test is one of the critical criteria where you submit a steel bar sample to tension which is under control until failure stageType 304 has an ultimate tensile strength of 51,500 psi, yield strength of ,500 psi and 40%The Old Metallurgical Engineer and Steelmaker says If you mean steel reinforcing bars for concrete, then 50,000psi and 60,000psi yield strength are quite common But if you mean other steel bars, the yield strength can vary from 41,300psi to 116,000psi

Minimum Yield Strength An Overview Sciencedirect Topics

Structure Magazine New Trends In Reinforcing Steel High Strength Reinforcing Bars

Hookes Law a >>> Elastic limit b >>> Yield point c >>> Ultimate strength d >>> Rupture strength Apparatus UTM, test specimen, vernier calliper etc Procedure a) I prepared a test specimen of about 2ft b) I measured its diameter by help of vernier calliper three times and took its average c) Then I inserted suitable jaws in the grips and selected suitable scale on testing machineSteel Bar Tensile Strength, Steel Bar Yield Strength & Length Stainless Steel Round Bar Tensile Strength ASTM 76 Square Bar, ASTM 79 Hex Rod, ASME S79 Bright Bar & AMS 5639 Bar Yield Strength 304, 316 and 316/L (UNS S & S) Flat Bar LengthYield Strength MPa minimum Tensile Strength MPa minimum Specimen Elongation in 0 mm percent minimum Handling Angle Degree Diameter of pin (d=nominal of diameter of specimen) Color Marking;

High Tensile Steel An Overview Sciencedirect Topics

Reinforcing Bar

A36 steel has a Poisson's ratio of 032, and a shear modulus of 78 GPa (11,300,000 psi) A36 steel in plates, bars, and shapes with a thickness of less than 8 in (3 mm) has a minimum yield strength of 36,000 psi (250 MPa) and ultimate tensile strength of 58,000–80,000 psi (400–550 MPa)Yield Strength 230 MPa min Tensile Strength 435 515 MPa Elongation % on gauge length ofThe Yield Point is in mild or mediumcarbon steel the stress at which a marked increase in deformation

Www Acifoundation Org Portals 12 Files Pdfs Crc 81 Determination Of Yield Strength Pdf

Types Of Rebar Used In Reinforcement What Is Rebar

41 atlas m10 carbon steel bright bar 29 42 atlas m1030 carbon steel bright bar 31 43 atlas 1045 mediumtensile carbon steel bar 33 44 atlas 1214fm free machining steel bright carbon bar 36 45 atlas 12l14fm free machining steel bright carbon bar 38 46 atlas 4140 through–hardening low alloy steel bar 40 47 atlas 65 throughAmir azlan 6 0 I have a flat steel bar (30 mm width, 5 mm thick, 1100 mm long) The bar has a load applied in the centre of 100N the bar is fixed at both ends with a single concentrated load P applied midspan the maximum yield stress is 250 MPa (250x10^6 Pa)Proof Strength or Offset Yield Strength (Rp02, 02% Offset Yield) Tensile Strength (Rm) Elongation at Maximum Force (Ag, Agt) Elongation after Fracture (A) Static material testing machines are available in a wide range of standard load capacities, generally from 250 kN to 10 kN

Reinforcement Bar Properties Youtube

Final Mild Steel Reinforcement Bar Tensile Properties Download Table

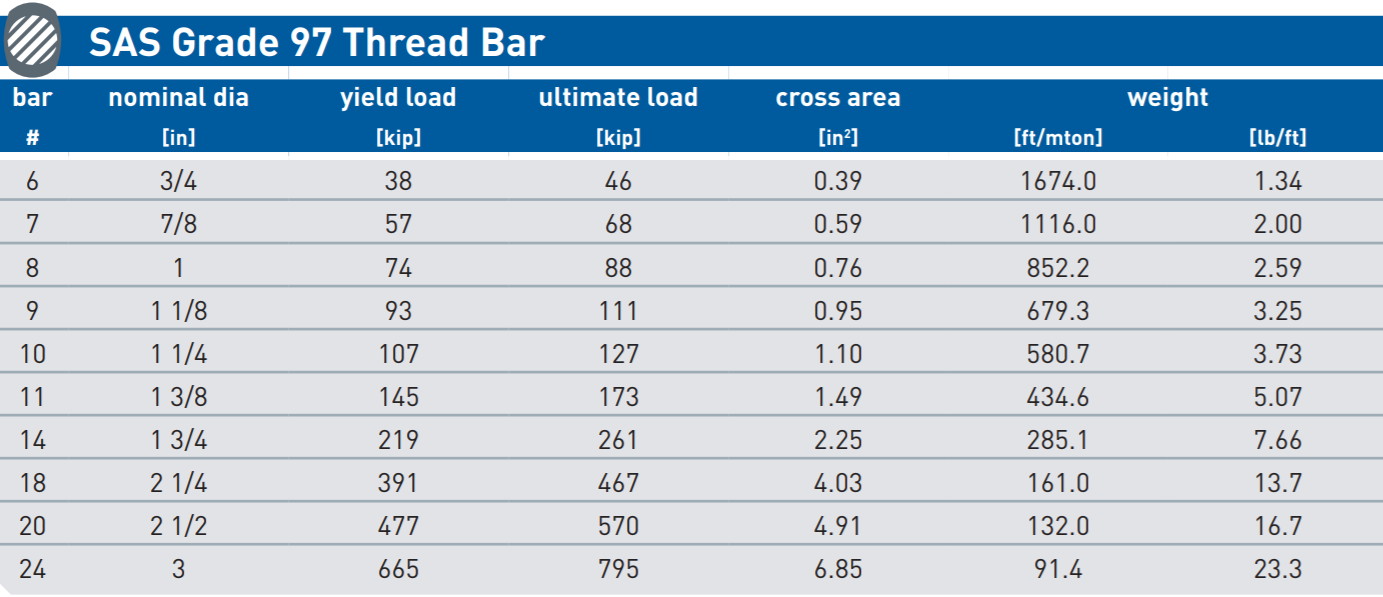

Yield strength is the maximum stress that can be applied before it begins to change shape permanently This is an approximation of the elastic limit of the steel If stress is added to the metal but does not reach the yield point, it will return to its original shape after the stress is removedPrimary variables included reinforcement yield stress and the ratio of tensiletoyield strength (ft/fy) An additional aim of the tests was to determine the minimum uniform elongation (strain at peak stress) and fracture elongation required of highstrength reinforcing bars for use in earthquakeresistant structuresPrimary variables included reinforcement yield stress and the ratio of tensiletoyield strength (ft/fy) An additional aim of the tests was to determine the minimum uniform elongation (strain at peak stress) and fracture elongation required of highstrength reinforcing bars for use in earthquakeresistant structures

Steel Material Properties Steelconstruction Info

Stress Strain Curve Wikipedia

Primary variables included reinforcement yield stress and the ratio of tensiletoyield strength (ft/fy) An additional aim of the tests was to determine the minimum uniform elongation (strain at peak stress) and fracture elongation required of highstrength reinforcing bars for use in earthquakeresistant structuresTensile tests of these steel samples were conducted under displacement controlled mode to capture the complete stressstrain curves and particularly the postyield response of the steel bars From the study, it can be concluded that Grade 4 performed higher TS/YS ratios and they were able to reach up to more than 125

Suj2 Bearing Steel Jis G4805 Steel Garde Material Standard Special Steel China Supplier Otai Special Steel

High Strength Reinforcement Systems Hsrs

Answered A Ductile Hot Rolled Steel Bar Has A Bartleby

1045 Ihcp Bar 75 Yield Strength 1045 Chrome Plated Steel

Steel Reinforcement For Concrete Masonry Ncma

Astm Sae Aisi 1045 Carbon Steel Heat Treatment Chemical Composition Properties

Grade Guide A36 Steel Metal Supermarkets Steel Aluminum Stainless Hot Rolled Cold Rolled Alloy Carbon Galvanized Brass Bronze Copper

Q Tbn And9gcsehelgzwfi9x6hksqbkw7gtegdfogr Bf19ieop2e9y7j Jawr Usqp Cau

Structure Magazine New Trends In Reinforcing Steel High Strength Reinforcing Bars

Grades Of Steel Yield Strength Tensile Strength Elongation All Explain Youtube

Carburized Steel Core Strength And Fatigue Life As A Function Of Hardness Bar Fatigue Blog

China Reinforcing Steel Bars With Yield Strength At 500mpa China Reinforcing Steel Bars Rebar

Faizan Steel Deformed Steel Bars Grade 60 Astm A615 A615m Faizan Steel Is One Of The Largest Manufacturers Of Deformed Steel Bars In Pakistan These Bars Comply With Astm A615 American Standards

.jpg)

Structural Steel S235 S275 S355 Chemical Composition Mechanical Properties And Common Applications

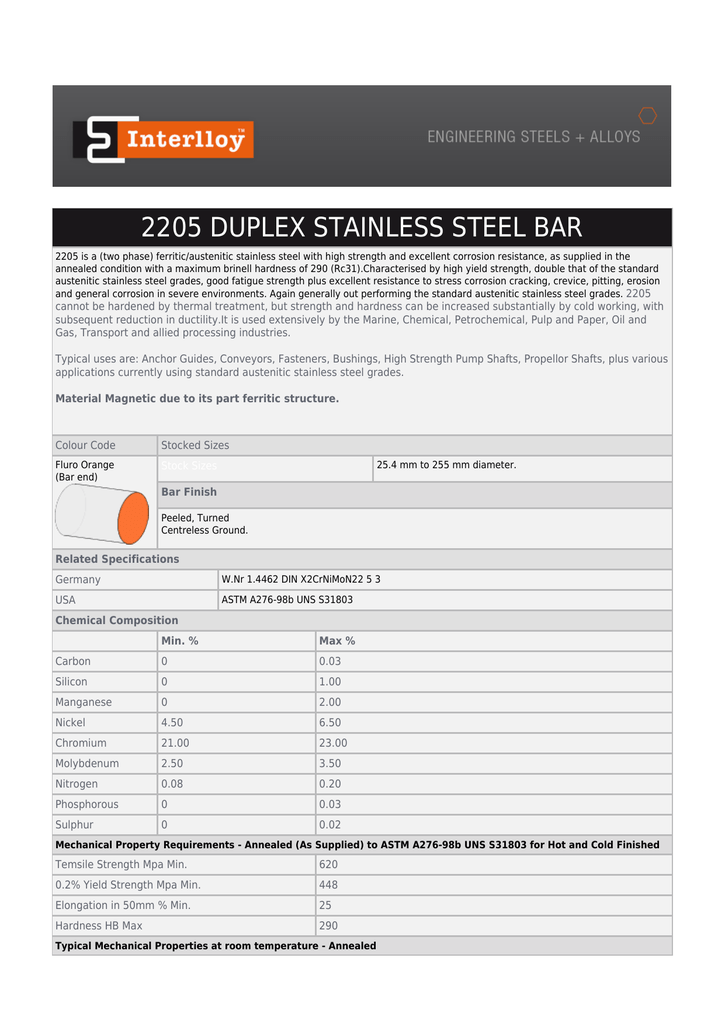

25 Duplex Stainless Steel Bar

Mohupa

Difference Between Mild Steel And High Tensile Steel Compare The Difference Between Similar Terms

Www Utoledo Edu Engineering Faculty Serhan Guner Docs B5 Vt5materialproperties Pdf

Exploring The Stress Strain Curve For Mild Steel The Chicago Curve

Q Tbn And9gctfhynwctdjitnm Wxngdidsrra1sn7xfp 93gj4awuklutpon7 Usqp Cau

Analysis Of International Standards On Concrete Reinforcing Steel Bar

Pdf Evaluation Of The Maximum Yield Strength Of Steel Stirrups And Shear Behavior Of Rc Beams Semantic Scholar

What Is Rebar Types And Grades Of Steel Reinforcement

Mechanical Properties Of Steel Frp Composite Bar Under Uniaxial And Cyclic Tensile Loads Journal Of Materials In Civil Engineering Vol 22 No 10

Flexural Behavior Of Beams Reinforced With Steel Bars Exceeding The Nominal Yield Strength

Mechanical Properties Of The Steel Bars Download Table

What Is Hysd Steel Bars Hysd Stands For High Yielding By Shyamsteel Medium

Mohupa

Final High Yield Steel Tensile Strength Properties High Yield Steel Bar Download Table

Tensile Strength Of Steel Yield Ultimate Tensile Strength Civil Sir

Yield Strength Of Steel Reinforcement Bars Yegna Trading

Verification Of Mechanical Properties Of Reinforcement Steel Bars Used In Nigerian Local Building By Iconic Research And Engineering Journal Issuu

To Determine Yield Strength Tensile Strength Of A Steel Bar By Offset Secant Method

Astm A615 Reinforcement Bar A615 60 Grade Steel

Effects Of Rust And Scale Of Reinforcing Bars On The Bond Performance Of Reinforcement Concrete Journal Of Materials In Civil Engineering Vol 26 No 4

Solved A Steel Bar Ab Of Diameter D And Yield Strength S Y Supports An 1 Answer Transtutors

What Is The Ultimate Tensile Strength And Yield Strength Of Mild Steel And Hysd Bar Quora

Stress Strain Curve For Steel Bars Stress Strain Curve For Concrete And Steel

Solved Q 1 A Ductile Hot Rolled Steel Bar Has A Minimum Y Chegg Com

China Grade 0 930 1080mpa High Yield Strength Screw Thread Steel Bar China Screw Thread Steel Bar Stress Bar

Flexural Behavior Of Beams Reinforced With Steel Bars Exceeding The Nominal Yield Strength

Q Tbn And9gcsl2ucpqiwc9opufsh1s27vhkuksaptqmjxuzcqphqraujpgbr2 Usqp Cau

Answered Question 2 A Ductile Hot Rolled Steel Bartleby

What Is 40 Grade 60 Grade Steel Bar Civil Engineering

Seminar Assignments Answers To Assignment 1 Studocu

Chrome Plated Hollow Steel Round Rod High Yield Strength And Tensile Strength

Steel Reinforcement For Concrete Masonry Ncma

What Is Rebar Why Use Reinforcement In Concrete Types Of Steel Reinforcement Bars

Ultimate Tensile Strength Wikipedia

Tensile Strength Of Steel Vs Yield Strength Of Steel Clifton Steel

Influence Of Geometric And Material Characteristics On The Behavior Of Reinforced Concrete Beam Column Connections

1018 Cold Drawn Steel Bar Supplier Cd 1018 Bar Eaton Steel Bar Company

.jpg)

High Yield Steel Properties And Capacities

Steel Reinforcement Types And Their Properties

Steel Reinforcement Types And Their Properties

Re Bars Tensile Yield Strength Test Machine Buy Tensile Yield Strength Test Machine Re Bars Tensile Yield Strength Test Machine Yield Strength Test Machine Product On Alibaba Com

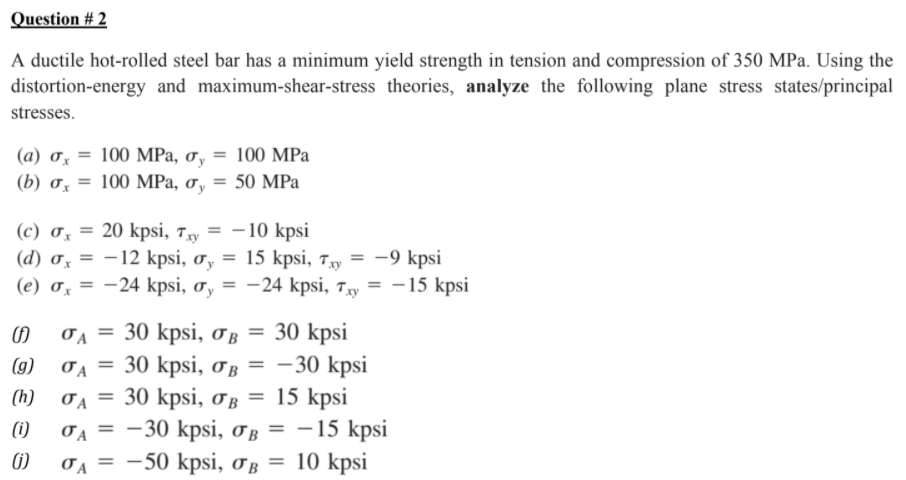

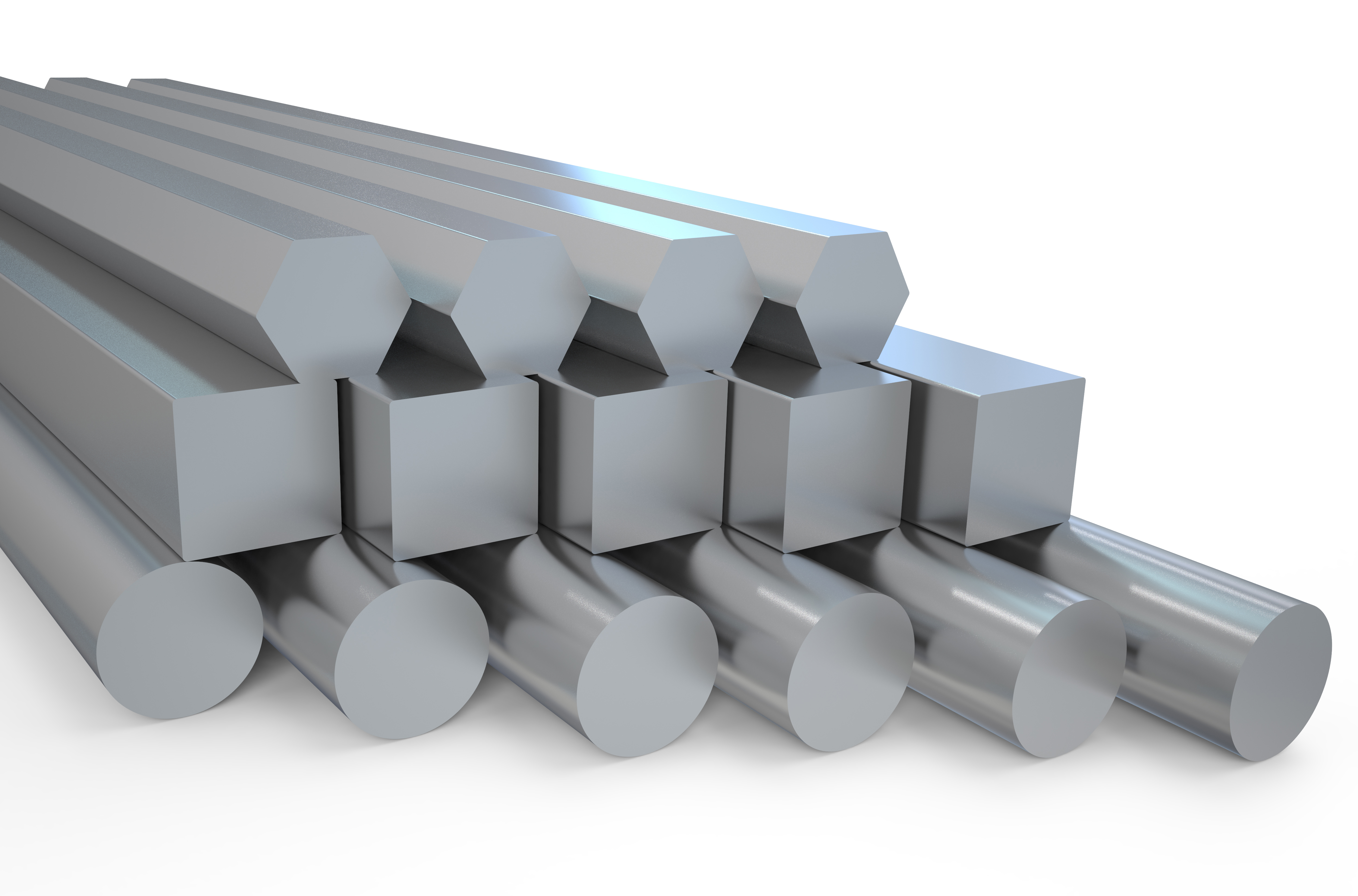

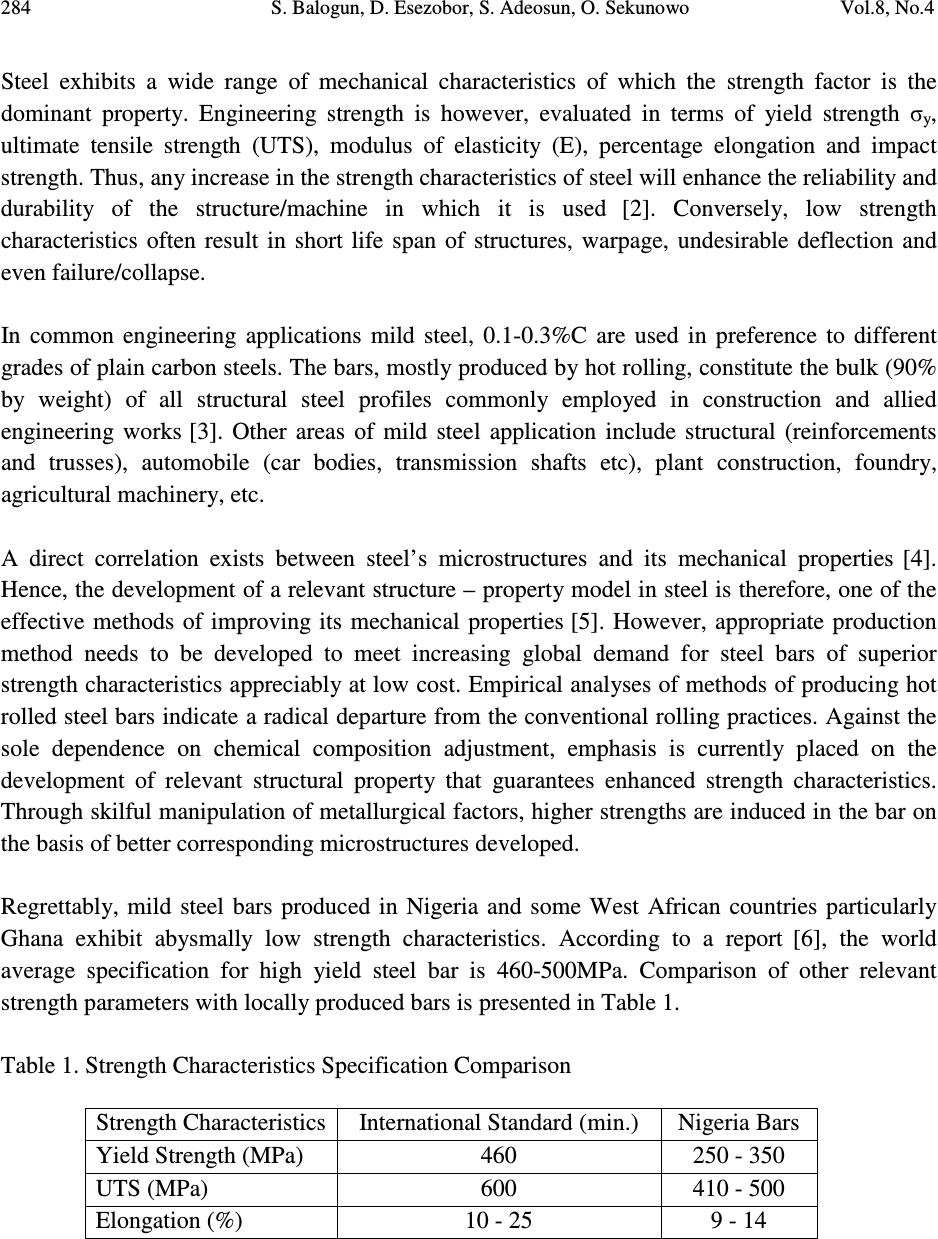

Challenges Of Producing Quality Construction Steel Bars In West Africa Case Study Of Nigeria Steel Industry

Mechanical Properties Of Steel Frp Composite Bars Under Tensile And Compressive Loading

Pc Steel Bars Steel Bar Steel Bar

Construction Updates Laboratory Tests On Mild Steel Reinforcement Steel

Astm 06 Grade 80 Reinforcement

High Yield Strength Deformed Steel Bar Price Grade 60 Deformed Steel Bar In Philippines Buy Deformed Steel Bar Deformed Steel Bar Price Deformed Steel Bar Grade 60 Product On Alibaba Com

Solved 3 27 A High Yield Strength Alloy Steel Bar With A Chegg Com

4140 4142 Steel Steel Quote 3 Prices

High Strength Reinforcement Systems Hsrs

Finding 0 2 Offset Strain Dplot

Important Information About Steel Engineering Infinity Facebook

Hot Rolled Vs Cold Rolled Steel Capital Steel Wire

Grades Of Steel Used In Construction Steel Grades In Indian Standard

What Is Rebar Types And Grades Of Steel Reinforcement

Chapter 2 Bond Behavior Of Reinforcing Steel In Ultra High Performance Concrete October 14 Fhwa Hrt 14 090

Concrete And Rebar Form Combined Footing

What Is The Relationship Between Hardness Tensile Strength Compressive Strength And Elongation Quora

Comparative Analysis Of The Tensile Strength Of Bamboo And Reinforcement Steel Bars As Structural Member In Building Construction Semantic Scholar

Tensile Strength Of Steel Vs Yield Strength Of Steel Clifton Steel

Draw The Not Yielding Envelope Of Mss And De Theory And Then Show All The Load Lines Homeworklib

コメント

コメントを投稿